rullaluistemadka silinda wadada XCMG wadada dayactirka rullaluistemadka

Silinder

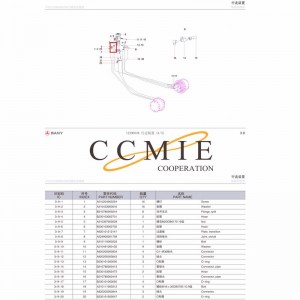

Sababtoo ah waxaa jira noocyo badan oo qaybo ka mid ah, ma soo bandhigi karno dhamaantood mareegaha. Fadlan xor u noqo inaad nala soo xiriirto qaar gaar ah

Faa'iidada

1. Waxaanu kuu soo bandhignaa badeecadaha asalka ah iyo kuwa dambe labadaba

2. Laga soo bilaabo soo saaraha ilaa macaamilka si toos ah, badbaadinta kharashkaaga

3. kaydka xasilloon ee qaybaha caadiga ah

4. Waqtiga Bixinta Waqtiga, oo leh kharash dhoofin tartan ah

5. Xirfadle iyo wakhtiga adeegga kadib

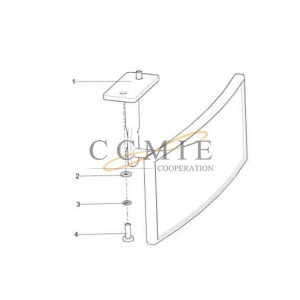

Baakad

Sanduuqyada Kartoonka, ama sida waafaqsan codsiga macaamiisha.

sharaxaad

Dhululubada Haydarooliga waxa loo qaybin karaa biisitoon cylinder\plunger cylinder iyo dhululubo lulid oo ka soo baxa qaab dhismeedka.

Silinders waxaa loo qaybin karaa dhululubada piston \ film cylinders \ dhululubada dib loo celin karo ee dhismaha.

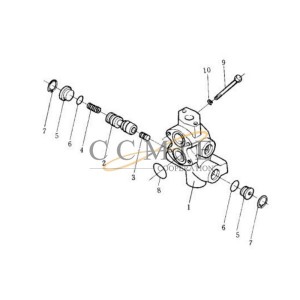

Mabda'a shaqada ee dhululubada haydarooliga waa: marka ay timaado mabda'a shaqada, waxaan marka hore ka hadli doonaa shanta qaybood ee ugu aasaasiga ah, 1-dhululubo iyo madaxa dhululubo 2-piston iyo bistoon rod 3-seal qalab 4-buffer 5- Qalabka qiiqa

Shaqada nooc kasta oo dhululubo ah waxay ku dhowdahay isku mid. Waxaan qaadan doonaa jaakadda gacanta si aan u muujiyo shaqadeeda. Jaakadu dhab ahaantii waa dhululubada ugu fudud. Saliidda biyo-mareenka waxa lagu sameeyaa xoojiye gacanta (matoorka gacanta). Ka dib markii hal waalle uu galo dhululubada, saliidda hydraulic ee gasha dhululubada dib dambe looma beddeli karo sababtoo ah halbeegga keliya, oo ku qasbaya usha dhululubo kor u kaca, ka dibna shaqadu way sii socotaa si ay u sii wado saliidda hydraulic si ay u sii gasho dhululubada. way sii kacaysaa, wayna soo dhici doontaa. Waqtigaas, fur furaha hawo-mareenka si aad ugu celiso saliidda hydraulic taangiga. Tani waa shaqada ugu fudud, kuwa kalena waxaa lagu wanaajiyaa habkan.

Dhululubada Haydarooliga waa shay fulineed oo u beddela tamarta hydraulic tamar farsamaysan oo ku jirta nidaamka hawo-biyoodka. Cilladaha waxaa asal ahaan lagu soo koobi karaa cilladda dhululubada Haydarooliga, awood la'aanta in la riixo culeyska, iyo silbashada ama gurguurashada bistoonka. Maaha wax aan caadi ahayn in qalabku uu istaago sababtoo ah fashilka dhululubada hydraulic. Sidaa darteed, waa in fiiro gaar ah loo yeesho ogaanshaha fashilka iyo isticmaalka iyo dayactirka dhululubada hydraulic.

1. Cilladda ogaanshaha iyo daaweynta

1. Khalad ama cillad

Sababaha iyo hababka daawaynta waa sida soo socota:

(1) Xuddunta waalka ayaa ku dheggan ama daloolka waalka ayaa xannibmay. Marka waalka socodka ama dabada jihada ay ku dhegto ama daloolka waalka la xannibo, dhululubada haydarooliga waxay u nugul tahay cillad ama cillad. Waqtigaan, hubi wasakhowga saliidda; Hubi in wasakh ama kaydka kolloidal ay ku dhegan yihiin xudunta waalka ama ay xannibaan daloolka waalka; hubi xidhashada jidhka waalka, nadiifi oo beddel shaandhada nidaamka, nadiifi haanta saliidda, oo beddel dhexdhexaadiyaha haydarooliga.

(2) Usha bistoonka iyo dhululubada ayaa ku dheggan ama dhululubada haydarooliga ayaa xannibmay. Waqtigan xaadirka ah, iyadoon loo eegayn sida aad u maamushay, dhululubada haydaruurku ma dhaqaaqdo ama ma dhaqaaqdo wax yar. Waqtigan xaadirka ah, hubi in shaabaduhu ay aad u dhagan yihiin, in wasakhda iyo kaydka kolloidal ay galeen: in xariiqda dhidibka usha biistoonka iyo foosta dhululubada ay siman yihiin, in qaybaha xidhashada iyo shaabadu aanay ansax ahayn iyo in kale, iyo in kale. culaysku aad buu u weyn yahay. Wayn

(3) Cadaadiska xakamaynta ee nidaamka hydraulic waa mid aad u hooseeya. Iska caabinta xannibaadda ee dhuumaha xakamaynta ayaa laga yaabaa inay aad u weyn tahay, valve socodka si aan habooneyn ayaa loo hagaajiyaa, cadaadiska xakamaynta waa mid aan habooneyn, iyo isha cadaadiska waa la dhibaa. Waqtigaan, hubi isha cadaadiska xakamaynta si aad u hubiso in cadaadiska lagu hagaajiyo qiimaha la cayimay ee nidaamka.

(4) Hawadu waxa ay gashaa hab-dhiska Haydarooliga. Inta badan sababtoo ah waxaa ka daadanaya nidaamka. Waqtigan xaadirka ah, hubi heerka dareeraha ee haanta saliidda Haydarooliga, shaabadihii iyo kala-goysyada tuubooyinka ee dhinaca nuugista ee bamka Haydarooliga, iyo in miiraha nuugida saliiddu uu aad wasakh u yahay. Haddi ay sidaas tahay, waa in lagu daraa saliidda hadhka, xirmooyinka iyo tuubooyinka waa in la daaweeyaa, iyo walxaha shaandhada aan fiicnayn waa in la nadiifiyaa ama la beddelaa.

(5) Dhaqdhaqaaqa bilawga ah ee dhululubada hadhidarooliga waa mid gaabis ah. Xaaladda heerkulka hooseeya, saliidda hydraulic waxay leedahay viscosity sare iyo dareere liidata, taas oo keenta in dhululubada haydarooliga ay si tartiib ah u socoto. Habka hagaajintu waa in lagu beddelo saliidda hawo-mareenka iyada oo la adeegsanayo viscosity iyo waxqabadka heerkulka. Heerkulka hoose, isticmaal kuleyliyaha ama isticmaal mashiinka si aad u kululeyso si aad u kordhiso heerkulka saliidda marka aad bilowdo. Heerkulka saliidda caadiga ah ee nidaamka waa in lagu hayaa qiyaastii 40 ° C.

2. Culayska lama wadi karo marka la shaqaynayo

Tilmaamaha ugu muhiimsan waa joojinta aan saxda ahayn ee usha piston, riixid ku filan, xawaaraha hoos u dhaca, shaqada aan degganeyn, iwm. Sababaha waa:

(1) Ka daadanaya gudaha dhululubada hadhidarooliga. Diidashada gudaha ee dhululubada hadhidarooliga waxaa ka mid ah daadinta ay keentay shabbada jidhku ee haydarooliga, shaabadda usha biistoonka iyo daboolka daboolka, iyo xidhashada xad-dhaafka ah ee shaabadda biistoonka.

Sababta ka daadanaya shaabadda u dhaxaysa usha biistoonka iyo daboolka shaabadda ayaa ah in shaabadda oo laalaabtay, la tuujiyey, jeexantay, xidhantay, gabowday, xumaatay, qallafsantay, iwm. Waqtigan, shaabad cusub waa in la beddelaa.

Sababta ugu weyn ee xirashada xad-dhaafka ah ee shaabadda piston waa hagaajin aan habboonayn oo lagu sameeyay waalka kantaroolka xawaaraha, taasoo keentay cadaadis dhabarka ah oo xad-dhaaf ah iyo rakibida aan habboonayn ee shaabadda ama wasakheynta saliidda biyaha. Midda labaad waa in walxaha shisheeye soo galaan marka la isku yimaado oo tayada shaabaddu ma fiicna. Natiijadu waa dhaqdhaqaaq gaabis ah iyo daciifnimo. Xaaladaha daran, waxay dhaawac u geysan doontaa bistoonka iyo dhululubada, taasoo keenaysa ifafaale ah "jiidista dhululubo". Habka daawaynta waa in la hagaajiyo valve xakamaynta xawaaraha, oo la sameeyo hawlgallada lagama maarmaanka ah iyo hagaajinta iyadoo la raacayo tilmaamaha rakibidda.

(2) Diidashada wareegga hawo-mareenka. Oo ay ku jiraan daadinta alwaaxyada iyo xadhkaha haydarooliga. Habka dayactirka ayaa ah in la hubiyo oo la baabi'iyo daadinta dhuumaha isku xirka Haydarooliga iyadoo la shaqaynayo valve roga.

(3) Saliidda biyo-mareenka waxaa dib loogu celiyaa haanta saliidda iyada oo loo marayo waalka qulqulaya. Haddi wasakhdu gasho waalka buuxdhaafka ah oo ay camisho spool-ka, taasoo ka dhigaysa waalka buux dhaafka si caadi ah u furmo, saliidda biyo-biyoodku waxay dhaafi doontaa waalka buuxdhaafay oo waxay si toos ah ugu soo laaban doontaa haanta saliidda, taasoo keenaysa in aanay wax saliid ah soo galin dhululubada Haydarooliga. Haddii culeysku aad u weyn yahay, in kasta oo cadaadiska nidaaminta ee waalka gargaarka uu gaaray qiimaha ugu sarreeya, dhululubada hawo-qaadka weli ma heli karo riixista looga baahan yahay ficil joogto ah mana dhaqaaqo. Haddii cadaadiska hagaajintu uu hooseeyo, xoogga laf dhabarta ee loo baahan yahay weli laguma gaari karo sababtoo ah cadaadis aan ku filnayn, taas oo u muuqata inay tahay cadaadis ku filan. Waqtigaan, hubi oo hagaaji waalka qulqulaya.

3. Piston simbiriirixato ama gurguurto

Simbiriirixashada ama gurguurashada bisinka dhululubada hadhidarooliga waxay ka dhigi doontaa dhululubada haydarooliga inay shaqeyso mid aan degganayn. Sababaha ugu waaweyn waa sida soo socota:

(1) Gudaha dhululubada haydarooliga waa caajis. Qaybaha gudaha ee dhululubada haydarooliga ayaa si khaldan loo soo ururiyey, qaybuhu way qallafsan yihiin, xiran yihiin, ama dulqaadka joomatarigu ka badan yahay xadka, caabbinta ficilkuna aad buu u weyn yahay, sidaa darteed xawaaraha piston ee dhululubada haydarooliga ayaa isbeddelaya booska istaroogga, iyo simbiriirixdo ama gurguurto. Sababta ayaa inta badan sabab u ah tayada isku-ururinta qaybaha oo liita, nabarrada dusha sare ama feylasha birta ee ay soo saarto sintering, taas oo kordhisa iska caabbinta iyo yaraynta xawaaraha. Tusaale ahaan: bisinka iyo ul bistoonka ma aha kuwo diirada saaraya ama usha bistoonka ayaa foorarsan, booska rakibaadda ee dhululubada haydarooliga ama usha piston ee tareenada hagaha waa la dhimay, giraanta daboolka ayaa lagu rakibay si adag ama aad u dabacsan, iwm. Xalku waa in la hagaajiyo ama la hagaajiyo, la beddelo qaybaha dhaawacan oo meesha laga saaro feylasha birta.

(2) Saliid liidata ama mashiinada ka baxsan liidata ee dhexroorka dhululubada haydarooliga. Sababtoo ah piston-ka iyo dhululubada, tareenada hagaha iyo usha bistoonada dhamaantood waxay leeyihiin dhaqdhaqaaq qaraabo ah, haddii sifeyntu ay liidato ama dheesha hydraulic cylinder ay aad u liidato, waxay ka sii dari doontaa xirashada waxayna yaraynaysaa linearity ee khadka dhexe ee dhululubada. Sidan oo kale, marka piston-ku uu ka shaqaynayo dhululubada haydaruurka, iska caabbinta khilaafku waxay noqon doontaa mid weyn oo marmarka qaarkood yar, taasoo keenta silbasho ama gurguurasho. Habka ciribtirka ayaa ah in marka hore la shiido dhululubada haydarooliga, ka dibna loo diyaariyo bisinka iyadoo la raacayo shuruudaha u dhigma, shiidi usha bistoonka, oo la habeeyo gacanta hagaha.

(3) Bamka Haydarooliga ama dhululubada Haydarooliga ayaa hawada gasha. Cadaadiska ama balaadhinta hawadu waxay keeni kartaa in piston-ku simbiriiro ama gurguurto. Tallaabooyinka cilad-raadinta ayaa ah in la hubiyo bamka haydarooliga, dejinta qalab gaar ah oo qiiqa, oo si degdeg ah u shaqeeya qiiqa dhowr jeer inta lagu jiro istaroogga oo dhan.

(4) Tayada shaabadu waxay si toos ah ula xiriirtaa silbashada ama gurguurashada. Marka shaabadda O-ring loo isticmaalo cadaadis hooseeya, marka la barbar dhigo shaabadda U-qaabeeya, sababtoo ah cadaadiska sare ee dusha sare iyo farqiga weyn ee caabbinta dhaqdhaqaaqa firfircoon iyo kuwa taagan, way fududahay in la gurguurto ama gurguurto; cadaadiska dusha sare ee shaabadda U-qaabeeya ayaa kor u kaca cadaadiska Si kastaba ha ahaatee, inkasta oo saameynta daboolka ah ay si isku mid ah u wanaajisay, farqiga u dhexeeya iska caabbinta dhaqdhaqaaqa firfircoon iyo kuwa taagan ayaa sidoo kale kor u kaca, cadaadiska gudaha ayaa kordha, kaas oo saameeya bartinimada caagga. Sababtoo ah kororka caabbinta xiriirka ee dibinta, giraanta wax lagu dhejiyo ayaa soo foorarsan doonta dibnaha ayaa sii dheeraan doona. Sidoo kale way fududahay in la sameeyo silbasho ama gurguurasho. Si looga hortago in uu soo dhaafo, giraanta taageerada ayaa loo isticmaali karaa si uu u xasilo.

Bakhaarkeena1

Baakad iyo rar

- Kor u qaadista hawada sare

- Baabuur-qaadka qashinka ee Shiinaha

- Dib u warshadaynta qabow

- Khadka Cone Crusher

- Weedhaha Dhinac Qaadista

- Dadi Bulldozer Part

- Lifaaqa Forklift Sweeper

- Hbxg Bulldozer Qaybaha

- Qaybaha Matoorka Howo

- Hyundai Excavator Pump Haydarooliga

- Komatsu Bulldozer Qaybaha

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Qodista Haydarooliga Pump

- Qaybaha Liugong Bulldozer

- Qaybaha Spare Pump Sany Concrete

- Sany Excavator Spare Parts

- Qaybaha Matoorka Shacman

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Isku xirka Shaft Pin

- Shantui Bulldozer Control Shaft dabacsan

- Shantui Bulldozer Shaft dabacsan

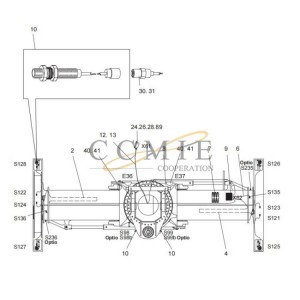

- Shantui Bulldozer Qalabka Dayactirka Silinder

- Shantui Bulldozer Qaybaha

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Qaybaha Spare

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Xirmada Dayactirka Sylinder ee Shantui Dozer

- Shantui Sd16 Bevel Gear

- Shantui Sd16 dahaarka biriiga

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Gacan-qaadashada

- Shantui Sd22 Xubinta Disc

- Shantui Sd32 Track Roller

- Qaybaha Matoorka Sinotruk

- Baabuur jiid

- Xcmg Bulldozer Qaybaha

- Xcmg Bulldozer Spare Parts

- Xcmg Haydarooliga Quful

- Gudbinta Xcmg

- Qaybaha Matoorka Yuchai